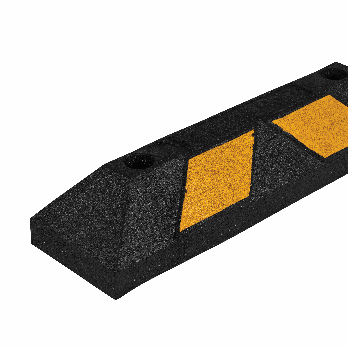

Rubber Parking Blocks

Description:

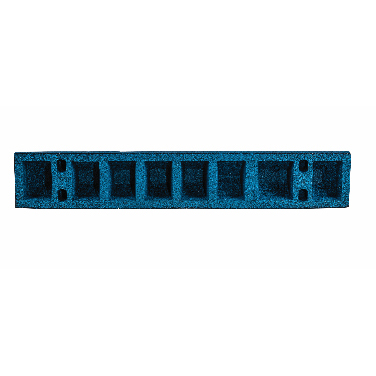

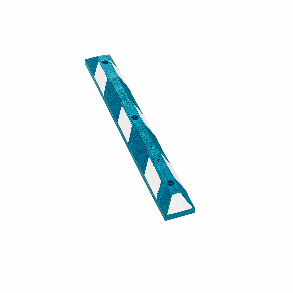

These car stops are constructed of 100% recycled rubber and used in parking lots to effectively stop cars pulling into parking spots. Unlike asphalt or concrete, which necessitate frequent replacements, rubber parking curbs are more forgiving of vehicles, sturdier, and do not break or need to be replaced. Rubber parking stops include in-molded, highly reflective tape in yellow or white, to ensure visibility and pedestrian safety. Our recycled rubber black and yellow parking bumpers are pre-drilled with holes. The flexible rubber design conforms to the contour of uneven road surfaces. ADA Handicap parking blocksare designed specifically for handicap parking spaces. The blue and white contrasting colors are immediately identifiable to differentiate handicap parking spaces to vehicles and pedestrians.

Colors available:

- Black rubber with yellow or white reflective tape

- Blue rubber with white reflective tape

Product Summary:

- Parking stop is made with corrosion resistant recycled rubber for long lasting durability and dependability

- Will not chip, crack, fade, crumble, rot or deteriorate. Resists tire scuffing.

- Resistant to damage from ultraviolet light and precipitation including ice, road salt, gas, and oil. Does not change with extreme weather swings.

- Molded highway reflective tape makes curb highly visible at night

- Flex slightly to conform to the contour of uneven surfaces and gravel

- Made of 100% recycled rubber making it 1/10th the weight of concrete curbs

- Long lasting and cost efficient

- Resistant to ultraviolet light, moisture, oil, and extreme temperatures

- No painting or maintenance needed

- ADA Handicap complaint blue parking stop

- Available in 3', 4', and 6' lengths

- Warranty: 3 years on the product; 1 year on the tape (under normal use)

WARNING:This product can expose you to chemicals including Arsenic, Cobalt, Cadmium, Lead, Chromium, Nickel Compounds, which is known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

Installation Method:

Installation on asphalt surfaces with rebar spikes 14” long (minimum diameter ½”)

(Recommended installation).

- 36inches (910mm) model – 2 spikes for installation

- 48inches (1219mm) model – 3 spikes for installation

- 72inches (1829mm) model – 4 spikes for installation

For installation with spikes the 0.5-inch (12.5mm) diameter holes are drilled through the holes in the product into a paved road then the spikes are hammered in.

- Installation on concrete surfaces with lag bolts 6” long (minimum diameter ½”), washer and shield

- 36inches (910mm) model – 2 lag bolts and shields for installation

- 48inches (1219mm) model – 3 lag bolts and shields for installation

- 72inches (1829mm) model – 4 lag bolts and shields for installation

For installation with lag bolts pilot holes 0.5 inch (12.5mm) are drilled through the product installation holes. The holes are re-drilled for a size required by the shields and the shields are installed. The product is then repositioned over the mounting holes and bolted down.