Whelen

Whelen Engineering began in 1952 when George W. Whelen developed a rotating aircraft "anti-collision beacon." This original concept was expanded to create a magnetic mounted beacon used by police, public safety, fire departments, and, to convert hearses to ambulance service! In 1963 Whelen began researching strobe light technology in order to introduce affordable, reliable and highly effective strobe products to the light aircraft industry and then to the automotive market.

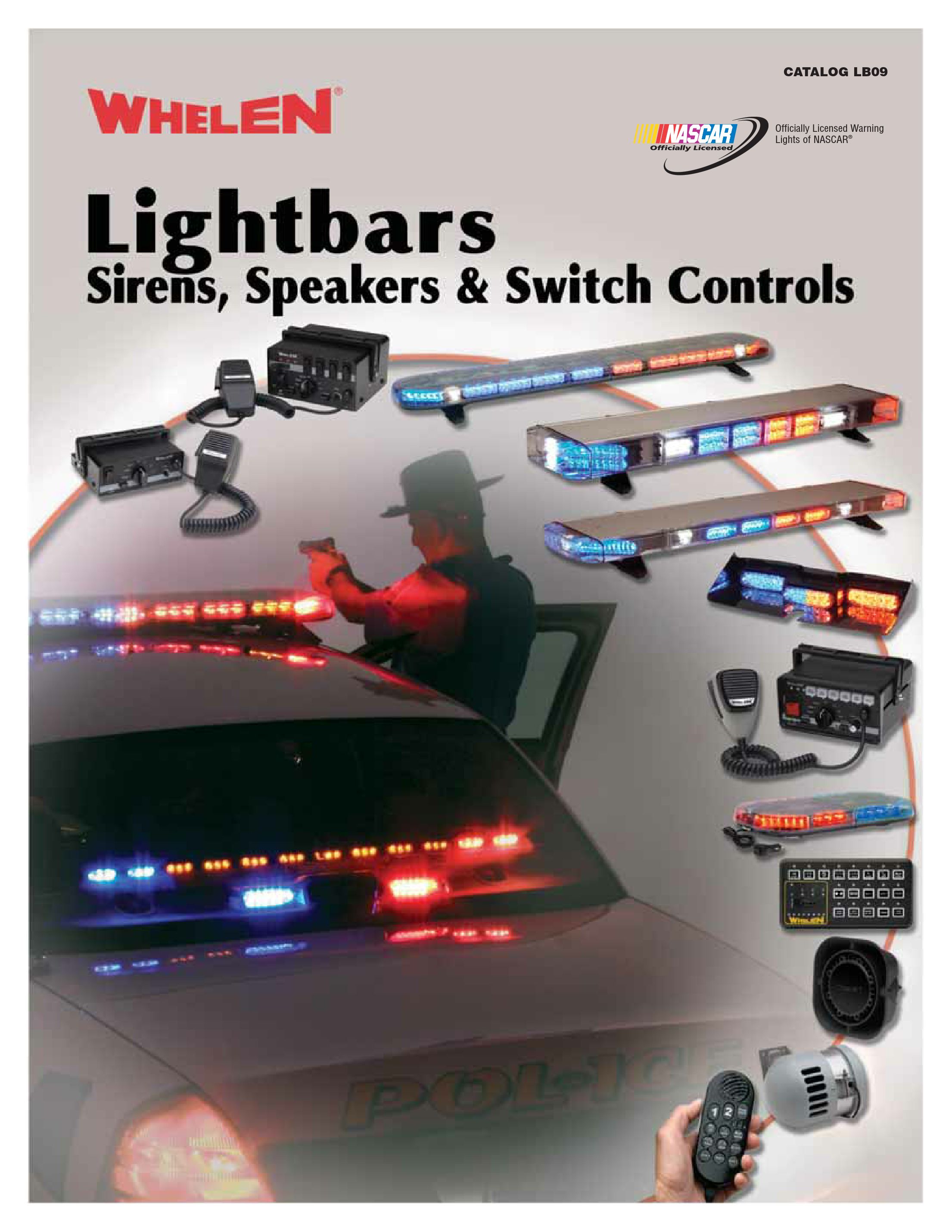

During the 1970's the company continued product development, adding more aviation products and a broader line of automotive and railroad safety lighting devices. The first all strobe enclosed crossbar was introduced as the 6000 Series, replaced in 1978 by the 8000 Series. The 70's also saw the introduction of the Outdoor Warning Siren ... totally electronic and capable of not just warning tones but also high-powered voice messages!

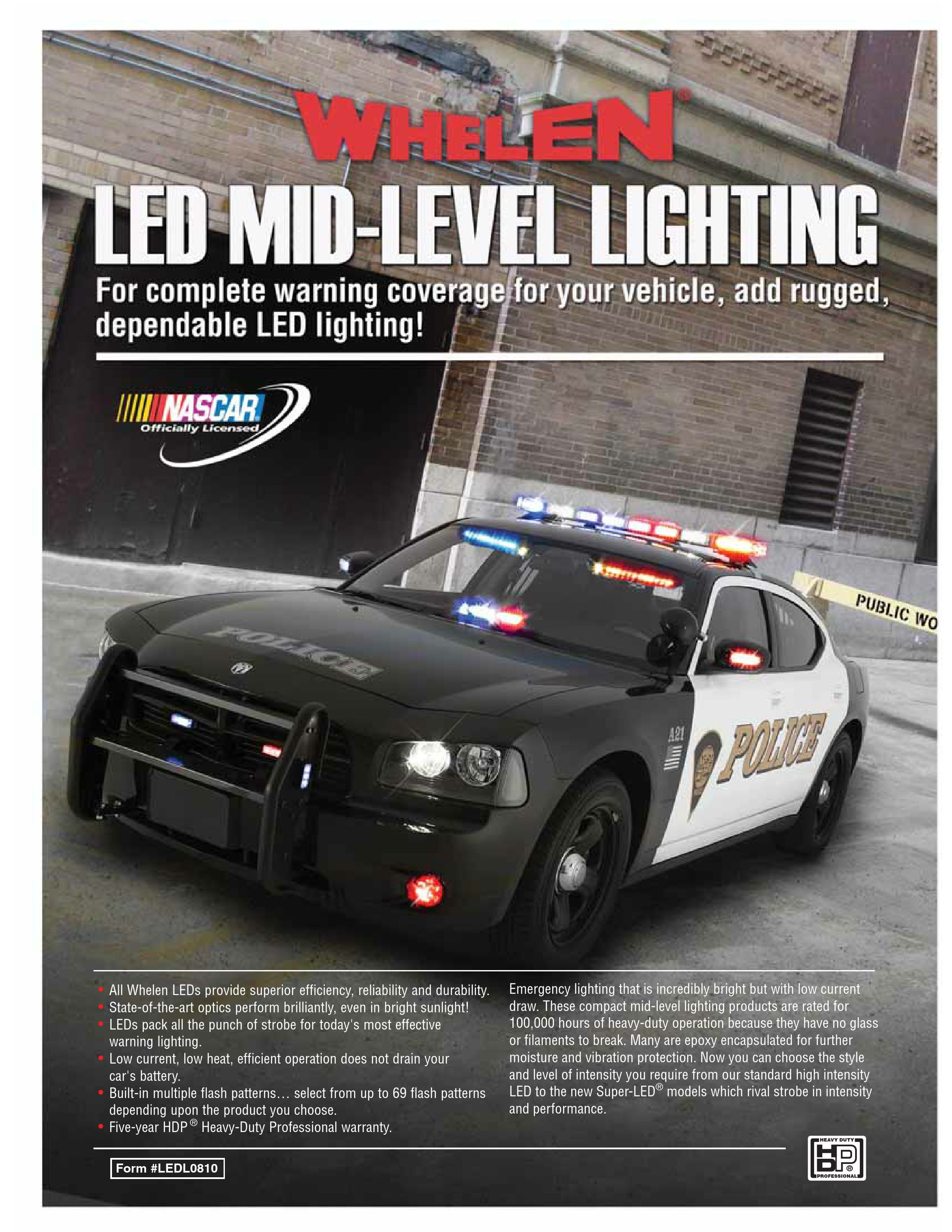

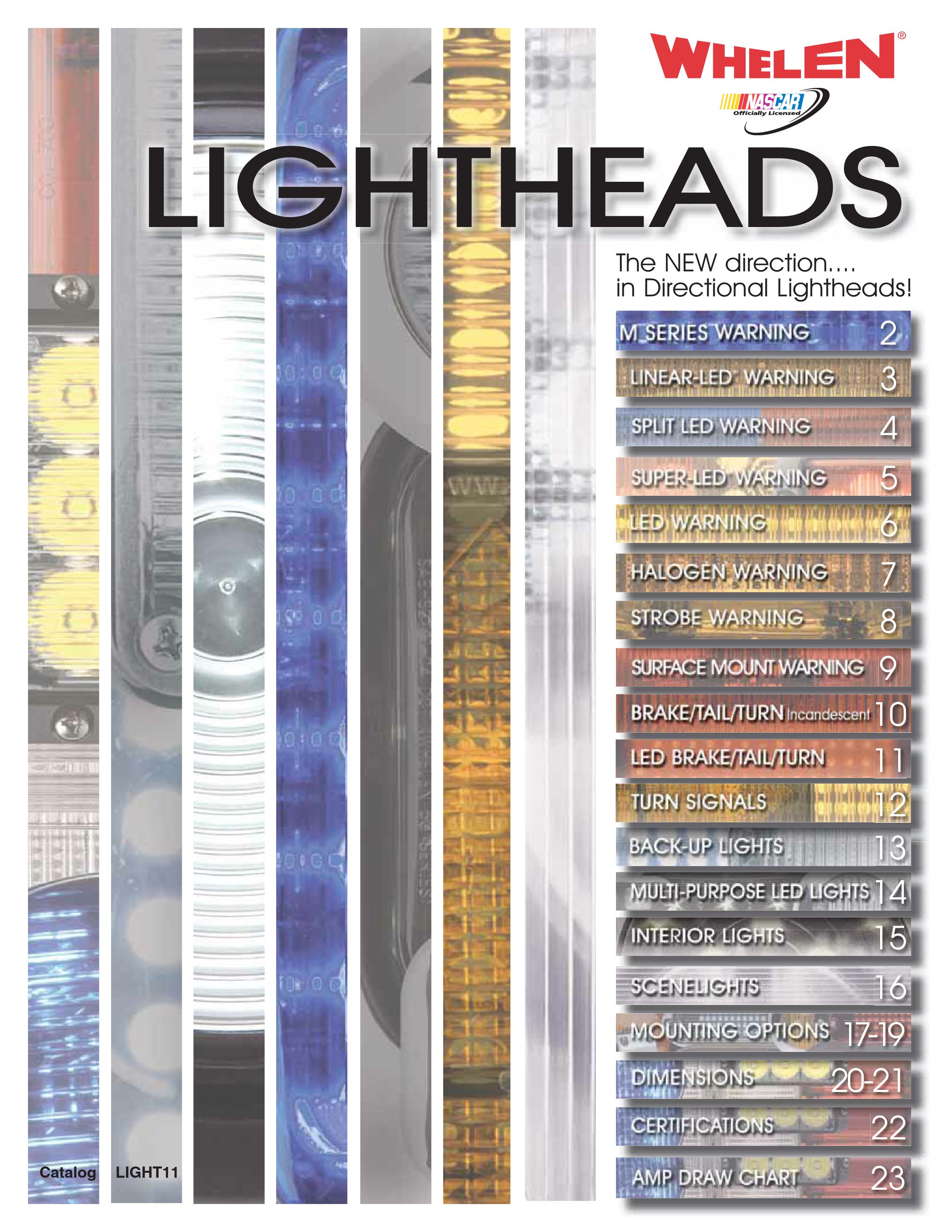

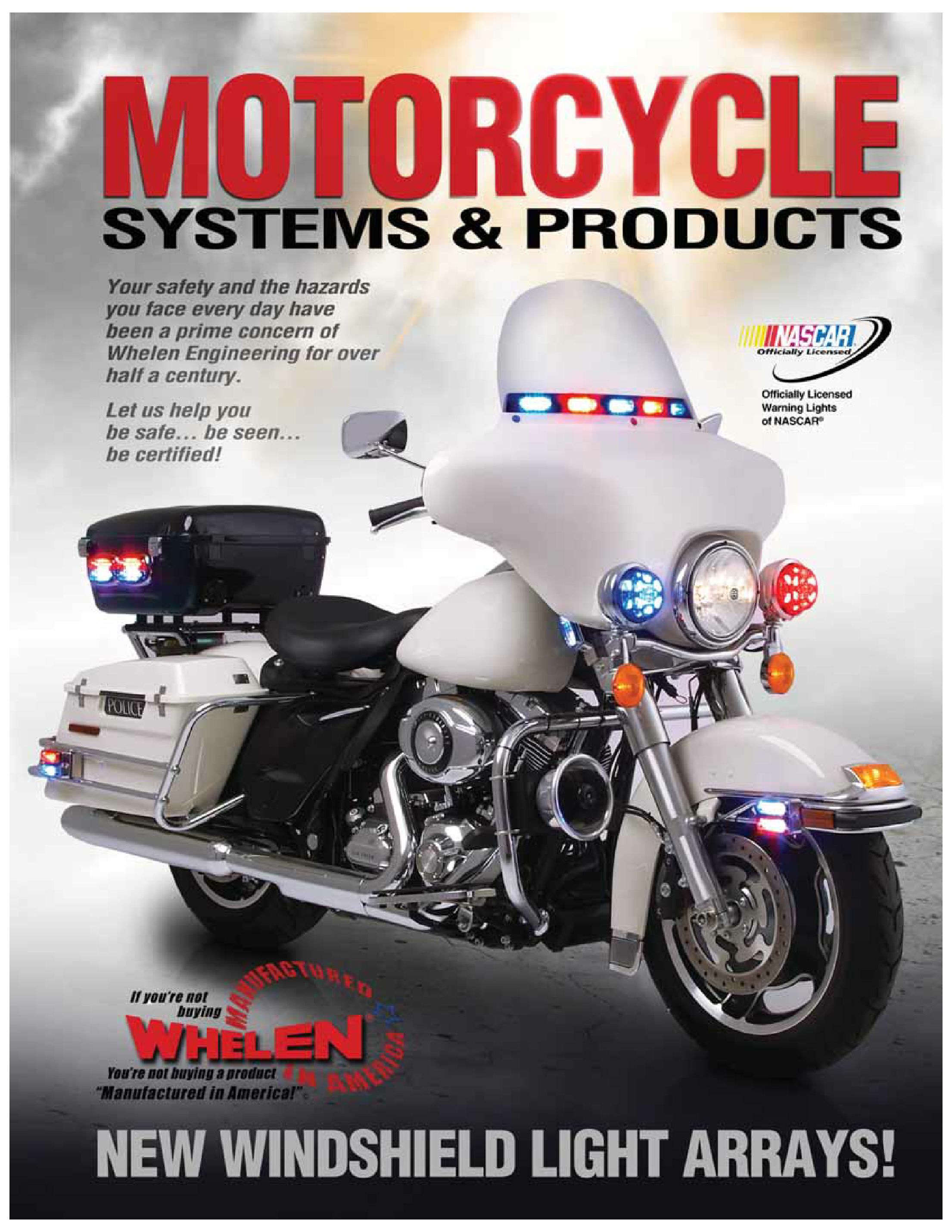

In 1983 Whelen announced a strategic advance- ment in lightbars, the low profile "Edge 9000" Lightbar. Refined and updated for over 20 years, the aerodynamic Edge lightbar remains an industry standard to the present day. Whelen also supported and developed the concept of uniform ambulance lighting, using more efficient and effective systems to reduce power consump- tion, thereby increasing the reliability of these vehicles. Strobe based technology expanded into ambulance, fire and rescue apparatus, railroad, police, DOT, marine and aviation applications. The 90's saw computer-networked vehicle warning systems, programmable warning equip- ment and instant operating diagnostics for safer vehicle operation. Voice and siren warning intelligence moved indoors for plant-wide employee warning systems. 1998 unveiled "Fasttrax", a slick roof line lightbar for the police market. By the year 2000, Whelen had designed and developed the newest LED technology to create a diverse line of lighting products with exceptional performance and reli- ability. Now available in ultra low profile lightbars, dash and deck lighting and a wide range of lighthead models, heavy- duty, low current LED's have quickly become the choice of fire, emergency and DOT professionals across the country.

In April 1987 Whelen added a second manufacturing site that quickly outgrew the leased facility and moved to the present location in the CEDA Industrial Park in Charlestown, NH. There, in a 10,000 square foot building, less than two dozen employees built sub-assemblies for the emergency warning products marketed by the parent company.

In 1991 the Charlestown plant was expanded to house the plastic injection molding equipment needed to produce the high quality, injection molded components vital to the product line. As demand for the highly regarded Whelen products grew, so did the company and today that facil- ity supports a work force of approximately five hundred people in a plant of over 285,000 square feet! Besides millions of plastic components, the Charlestown facil- ity manufactures a wide range of products from single beacons and power supplies to lightbars and complete lighting systems. Deep River Garage The garage workshop in Deep River, Connecticut has grown to a bustling 242,000 square foot plant in Chester. Sales, Service and Warehouses in twenty-five locations throughout the United States, Canada, Mexico and Europe support the three facilities in Chester, Charlstown and Coventry, England. The acknowledged leader in the industry, Whelen strives to fill the need for innovative safety warning systems with a large engineering staff backed by a state-of-the-art environmental testing laboratory. The pride and commitment of its work force, who's average employment longevity is 22 years, is rewarded by sharing the Company's benefits as share holders in the tradition established by the founding Whelen's fifty-six years ago.

Whelen is the only US manufacturer of emergency warning equipment to still manufacture its products entirely in the United States. The use of robotics and a motivated workforce allow it to compete with off-shore products.